Opting for reusable packaging can often seem like a tough and complex choice, involving logistical challenges and additional costs in particular. Yet practical application proves that things can be different. This was evident from the Reuse Field Trip organised by Fost Plus at the end of September. In this article, we share the five lessons learned with you.

For our field trip, we travelled to the German-speaking part of Belgium. Our first stop was a visit to the Delhaize and Carrefour branches in Eupen, where we learned about a pilot project run by La Conserverie & Moutarderie Belge (CMB), Foodprint and Bring Back.

Make it simple for consumers

In 2022, CMB launched a new product line of mustard, sauces, olives and sandwich fillings under the Maria & Franz brand name in reusable glass jars with a 15-cent deposit.

"Thanks to the pilot project, consumers can now also return the packaging via the traditional return machines that are also used for beer and drinks bottles with deposits. By connecting to consumers' existing habits, you make it easier for them and increase the likelihood that they will actually return the packaging," says Anne Poggenpohl, Reduce & Reuse Expert at Fost Plus.

Take your marketing strategy into account

The reusable packaging initially came at the request of a major German customer, but CMB saw a unique opportunity to go a step further. "By launching a new brand in reusable packaging, you can learn faster and also better position the products to appeal to aware consumers. You can see this in the shops in Eupen, too. Maria & Franz products are given a full shelf there, a real reuse shelf. The in-store displays inform consumers that there is a deposit on the packaging, but at the same time draw attention to the new product range on the shelves."

Carrefour is also experimenting in France with a separate ReUse Corner in its supermarkets, where consumers can purchase and return a wide variety of reusable packaging. By doing this, not only do you attract the attention of aware consumers, but it also creates clarity and opportunities for cross-selling. On the other hand, their tests also show that it is important to distribute products throughout the shop in the usual places where people look for these products.

It turned out that the reusable packaging offers CMB additional benefits. "Thanks to their own pool of reusable jars, they were better protected against fluctuating prices and scarcity in the market during the 2023 energy crisis. For SMEs especially, this can be particularly attractive.”

You don’t have to do everything yourself

CMB also took a unique approach to logistics. "As a producer, you are used to never seeing your packaging again. That changes completely when you switch to reusable packaging. CMB set up a separate organisation called Foodprint for the return logistics, with the idea in mind of offering the service to other manufacturers as well," says Anne Poggenpohl.

To wash the packaging, Foodprint relies on Bring Back, which opened the first industrial washing plant for glass bottles and jars in Belgium in February 2022. "The plant is unique mainly because of its flexibility. They can clean different types of glass containers there: large and small bottles, as well as jars like those of Maria & Franz. Thanks to a new investment, as of next year they will have the capacity to wash 80 million glass containers a year.

Benefit from a growing ecosystem

Foodprint and Bring Back illustrate that a real ecosystem is slowly emerging around reusable packaging. "We are seeing more and more players emerging that offer reuse-as-a-service and lighten the burden for producers in all sorts of ways: in-store collection, package cleaning, transport to and from production sites, deposit collection and refund management systems, and so on," says Anne Poggenpohl.

During our field trip, we were introduced to the German company Zerooo, which offers a smart pool system for cosmetics such as hand soaps, shower gels, shampoos and perfumes. "The key lies in the standardised container made of PET or glass, which simplifies the whole logistics process. By playing with colours, labels and caps, each brand can still create its own look and feel. To illustrate their approach, the company launched a successful cosmetics line of its own under the name Sea Me, which is already available in more than 1,000 shops in Germany and Austria.”

- Use the Reduce & Re-Use MatchMaker to find the right partner for your project!

Evaluate your business case in the long run

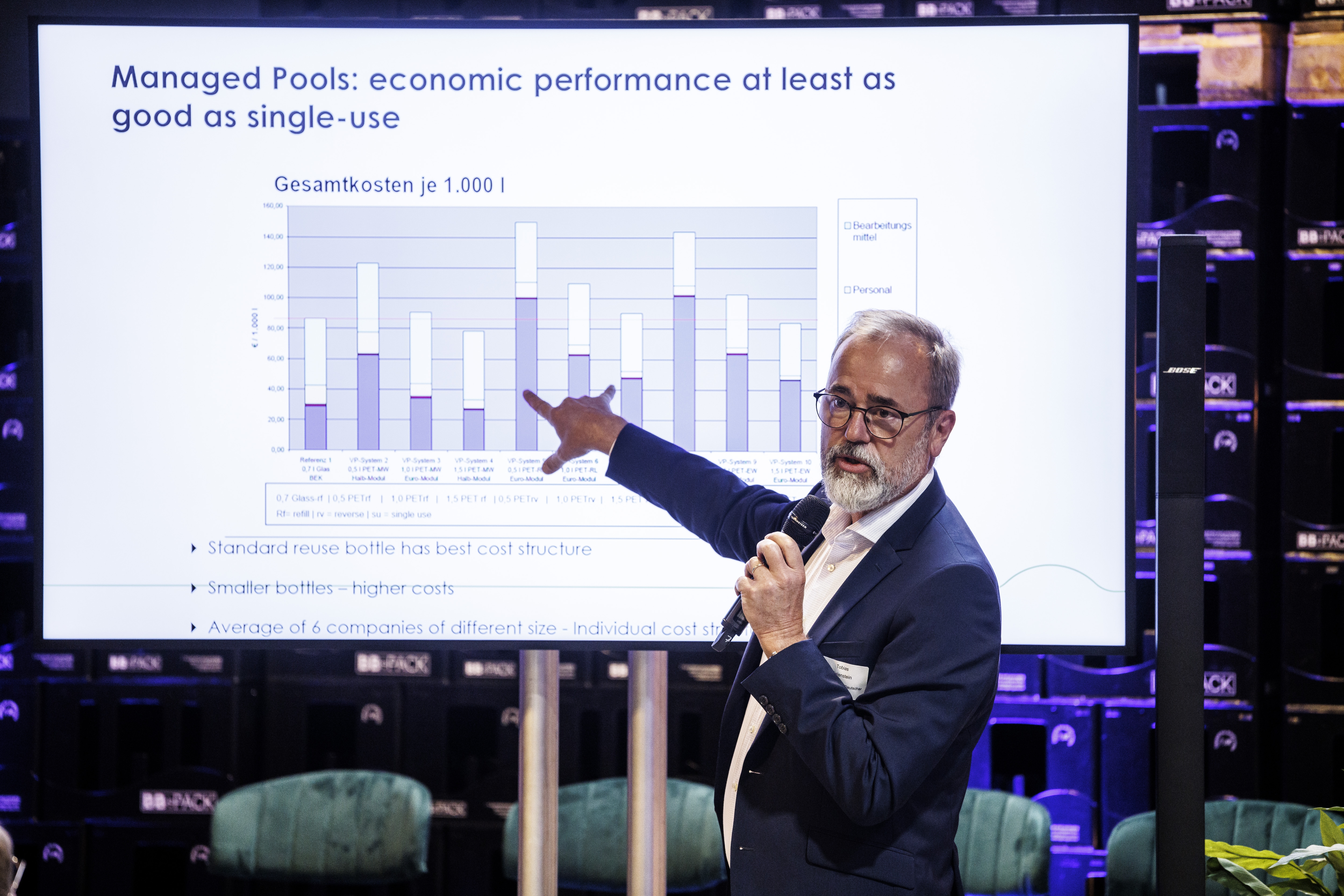

Besides the logistics aspect, the cost issue also raises a lot of questions. Yet it is a misconception that reusable packaging would be more expensive. "Above all, we see a high initial cost: you have to put enough packaging into circulation and get your logistics in order. It may also take some time to get customers used to the new system. But in the longer term, reusable packaging can make economic sense."

This was also confirmed during the presentation by Alken-Maes, which, like most Belgian brewers, has been using beer bottles with a deposit for decades. Last year the company decided to switch to reusable bottles with a deposit for its Desperados brand as well.

Of course, the prerequisite is that the return rate is high enough. "Even in a well-established system like beer bottles, there are still challenges in this domain," says Anne Poggenpohl. "In addition, brewers also have to deal with bottles that are too contaminated. Plus labels that do not wash off – especially from smaller brewers – sometimes make the bottles unsuitable for reuse. Good consumer communication is therefore essential, as their cooperation is decisive for long-term success."

The Reuse Field Trip was organized by Fost Plus, Comeos, Fevia, La Conserverie et Moutarderie Belge, Foodprint and Bring Back.

How can Fost Plus help you?

Do you want to explore the possibilities for reducing and reusing your packaging, but are unsure where to start? Are you looking for the right partners? Are you working on a reuse project but you have got stuck somewhere? Or you just want to share a successful experience? We'd love to hear about it! Get in touch with our Reduce & Reuse Team via the contact form.