At the Beerse site, home to over 4,000 members of staff, the teams have made waste collection a real corporate culture. We take a look behind the scenes of a large yet highly disciplined and well organised campus.

This very extensive site of Janssen Pharmaceutica in Beerse houses a wide range of departments, from production to administration as well as research and development. With a correspondingly diverse array of employees and waste, including PMD.

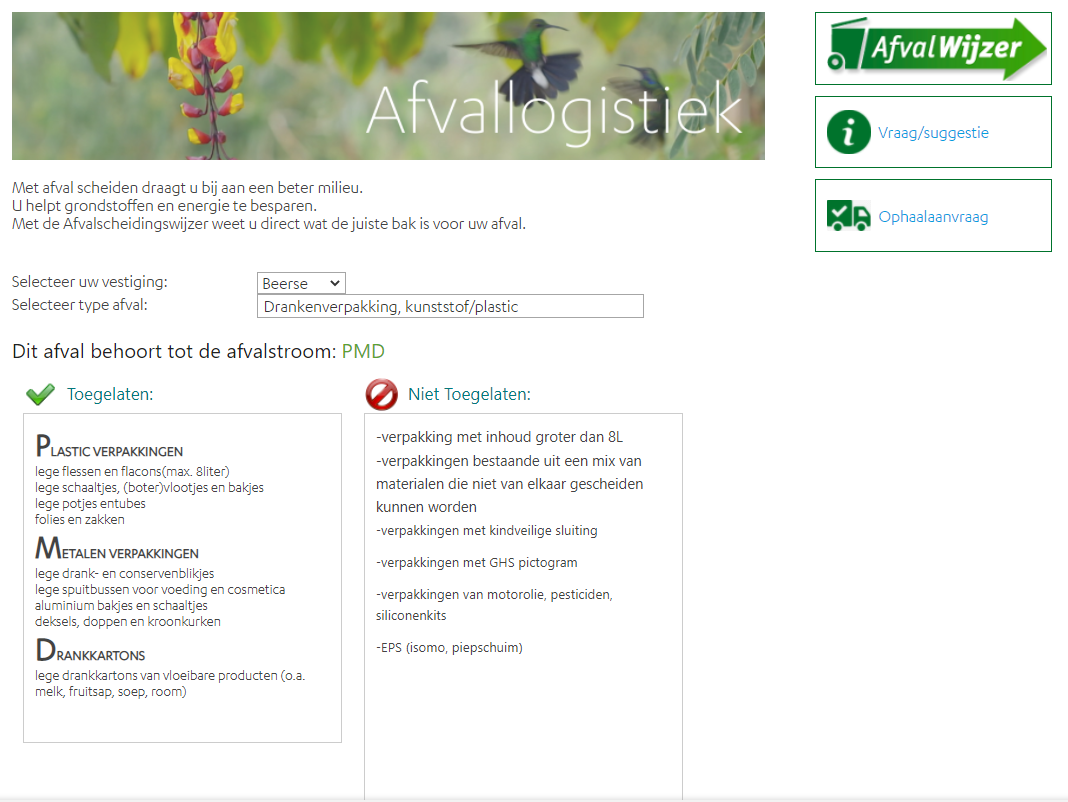

An extremely useful ‘waste app’

The wide variety of waste can sometimes cause confusion: what has to be sorted and which bin should I use? An internal app has been produced and is used on the intranet. It is known as the ‘Afvalwijzer’ (waste indicator).

Users select the type of waste they want to throw away and a very clear indicator appears, showing them which bin they have to put it in. The app also provides valuable information on the sorting rules, and on what is permitted or what is not. The PMD sorting rules used at home are also valid in the workplace.

The Janssen Pharmaceutica communication teams actively promoted this tool and the real involvement of colleagues and staff in sorting is assessed on a regular basis.

Sorting is rewarded on multiple levels

Those given the task of emptying the sorting islands take the opportunity, when cleaning, to analyse the contents and assess the sorting quality in the various departments. The better they sort, the better we can recycle. Every month, the department that has made the greatest sorting effort is rewarded with a luxury fruit basket.

And the efforts… bear fruit too, as the collection partner at the Beerse site, Renewi, recovers no less than around one tonne of PMD per month.

Team work

A waste ‘discipline team’ has been created to draw up procedures for all aspects of waste sorting and disposal on the site. This working group cooperates actively with the various departments. The discipline team puts forward recommendations on very practical and operational aspects of waste sorting and collection and supports the workforce as a whole. Together, the teams identify the positive points, the things that work well, but also the points in need of attention, the things that still need improving.

Great team work that pushes for constant progress.